Green manufacturing practices have gained significant attention in recent years as more companies strive to reduce their environmental impact and adopt sustainable business practices. With the growing concern over climate change and the depletion of natural resources, exploring green manufacturing practices has become essential for businesses across various industries. In this blog post, we will dive into the concept of green manufacturing and explore some of the key strategies that companies can adopt to achieve sustainable production processes.

Green manufacturing, also known as sustainable manufacturing or eco-friendly manufacturing, refers to the process of producing goods using methods that minimize the use of resources, reduce waste, and limit the release of harmful pollutants. Unlike traditional manufacturing practices that focus solely on maximizing productivity and profitability, green manufacturing takes a more holistic approach by considering the overall environmental and social impact of the production process.

One of the most crucial aspects of green manufacturing is resource conservation. Companies are increasingly adopting strategies such as energy-efficient equipment, waste reduction programs, and water conservation measures. By optimizing energy usage, businesses not only reduce their carbon footprint but also cut down on utility costs. Similarly, waste reduction programs help minimize the amount of waste generated during the production process, leading to lower disposal costs and a cleaner environment.

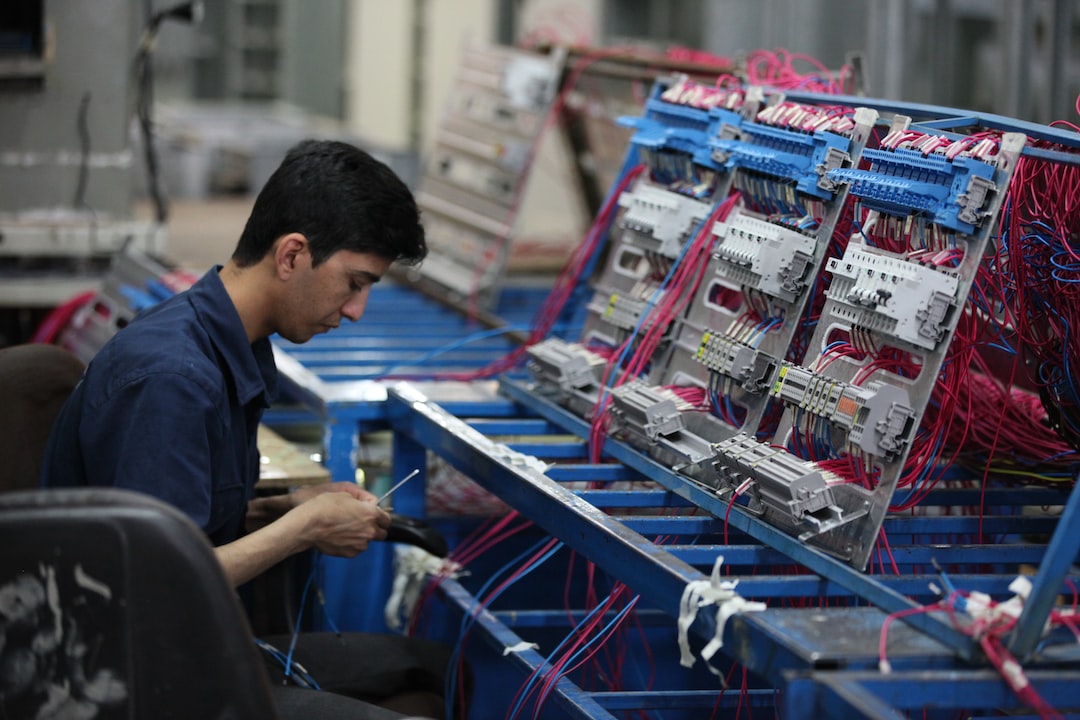

Advanced technologies and automation play a significant role in achieving green manufacturing objectives. Companies are investing in state-of-the-art machinery that is designed to be more energy efficient and produce less waste. Automation allows for precise control over production processes, minimizing errors and reducing resource consumption. Additionally, the integration of smart sensors and real-time monitoring systems provides valuable data that can help companies identify areas for improvement and optimize their operations further.

Another critical aspect of green manufacturing is the use of eco-friendly materials. Companies are increasingly turning to biodegradable, recyclable, and renewable materials in their production processes. For example, instead of using plastic packaging, businesses are adopting sustainable alternatives such as bioplastics or compostable materials. The use of eco-friendly materials not only reduces the environmental impact but also aligns with consumer preferences for sustainable products, thereby improving brand reputation and customer loyalty.

Collaboration with suppliers and stakeholders is crucial for achieving green manufacturing practices. Companies are increasingly evaluating their supply chain partners based on their sustainability practices. Engaging with suppliers who share similar environmental values and promote sustainable practices helps create a network of like-minded businesses working together towards a greener future. Clear communication and regular audits ensure that suppliers adhere to sustainability standards, leading to a more sustainable supply chain overall.

To encourage green manufacturing practices, governments and regulatory bodies are implementing various policies and initiatives. These include tax incentives for companies adopting sustainable practices, stricter environmental regulations, and certification programs such as LEED (Leadership in Energy and Environmental Design) for buildings. By aligning their operations with these regulations, businesses not only contribute to a sustainable future but also avoid potential penalties and demonstrate their commitment to environmental stewardship.

In conclusion, exploring green manufacturing practices has become essential for businesses looking to reduce their environmental footprint and promote sustainability. By adopting strategies such as resource conservation, advanced technologies, eco-friendly materials, collaboration with suppliers, and adhering to regulatory policies, companies can contribute to a greener future while also reaping the benefits of improved efficiency and cost savings. As the world becomes increasingly aware of the need for sustainable practices, implementing green manufacturing methods will not only drive positive change but also position businesses as pioneers in their respective industries.